Business-critical processes often rely on moving large amounts of data. Even things that customers take for granted—like a package showing up on time, for example—requires massive orchestration of data across complex systems.

Moving this data around quickly (and accurately) is crucial to preventing snafus and keeping costs down. But though critical, it can also be expensive and time-consuming to do. Custom integrations can be expensive to build and even more expensive to maintain—especially if you rely on external firms to do it for you.

Recently, robotic process automation (RPA) has emerged as an alternative to custom-built workflows. RPA, however, can’t necessarily complete all of the steps in these complex business processes, so companies still need to use other platforms.

This leaves them with a hodge-podge of integration and automation tools, each of which is good for only part of the process, and no way to tie them together.

Intelligent automation offers a different approach. By allowing you to use both traditional integration and automation alongside newer technologies like RPA, it can be the best of both worlds. Here’s how a leading logistics company uses Workato’s intelligent automation platform in conjunction with RPA to move, de-dupe, and sync crucial data quickly.

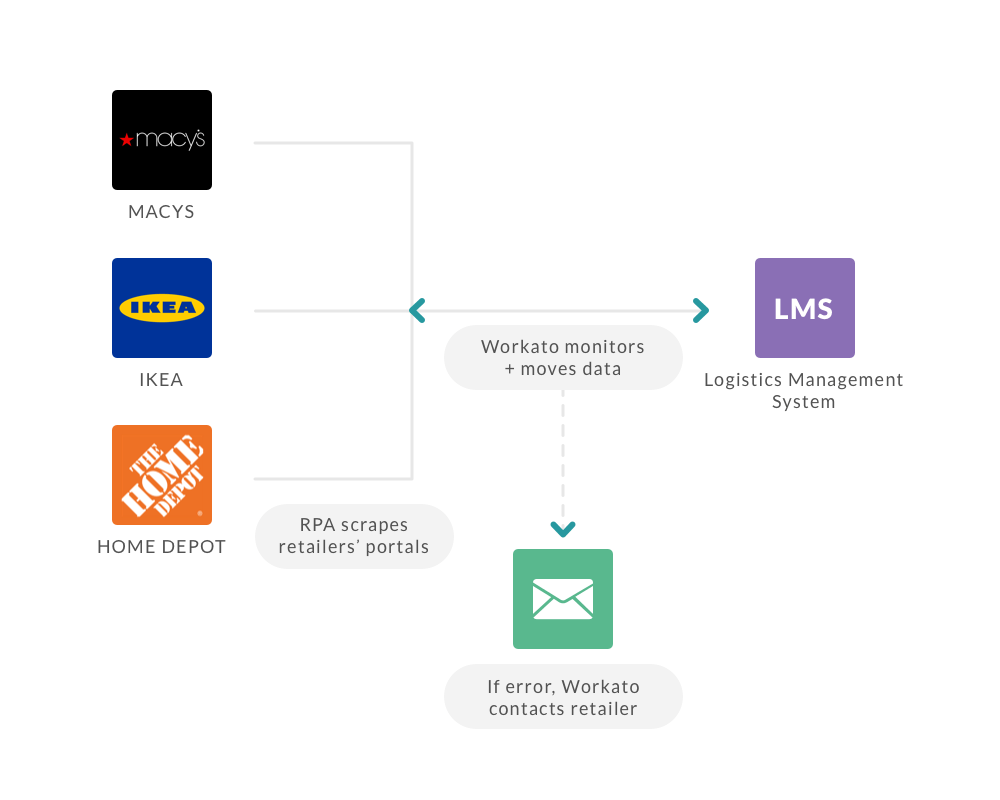

Who? A leading logistics company that provides delivery services to major retailers like Macy’s, Ikea, and The Home Depot.

What are they doing with Workato? Retrieving up-to-date shipment information from retailer portals, pushing the data into their logistics management system, and monitoring the process for errors.

The Challenge: The company needed a powerful way to grab this shipment information that would cost less than custom-coding and maintaining integrations.

The Solution: The company uses Workato in tandem with an RPA tool to pull data from retailer portals, move it into a central location, and monitor the entire process for errors or problems.

The Results:

- Cut the time it takes to build custom integrations from 450+ hours to an average of ~4 hours

- Always have up-to-date shipment information from the retailers they deliver for

- Can make the most of their RPA tool by complementing it with Workato’s intelligent automation capabilities

- Can automatically monitor and report issues, such as a down portal, that could prevent them from delivering packages on time

- Can focus on actions that require a human touch, rather than on troubleshooting issues

Related: A guide to EDI

From 450+ Hours to 4: Pulling Shipment Information from Retailer Portals with RPA

As a leading logistics provider, the company needs to fetch shipment information from its clients—large retailers like Macy’s, Ikea, and The Home Depot—every day. Because the retailers make this information available through dedicated portals and in different formats, it’s difficult to gather it manually.

Initially, the company tried using custom-coded automations to collect, check, and move the data into its internal logistics management system. But these custom connectors proved expensive and time-consuming to create and maintain, especially when taking security measures like OAuth 2.0 into account. Just one connector took 450+ hours to build!

On the other hand, RPA tools are a cheaper alternative and can easily collect data from the retailer’s portals. But they can’t execute the other steps in the process—like de-duping the data and reporting any errors.

As a solution, the logistics company chose Workato. Using a script built on top of an RPA tool, Workato collects data from the retailer portals every day. The intelligent automation platform then de-dupes and checks the data.

Because Workato can easily work with OAuth 2.0, it’s also much simpler to build integrations that are secure. Compared to the roughly 450 hours it took in the past, this approach is much faster; the company created the initial integration in only 4 hours!

Identifying Missing Shipment Information and Automatically Contacting the Retailer

Shipment information changes very quickly, and even a small error can prevent the logistics company from being able to make a delivery on time. When crucial information is missing from a shipment—such as an invoice number or PO number—the logistics company needs to contact the retailer ASAP about the error. Without automation, this is impossible to do at scale in real time.

As a solution, the company uses Workato to reach out to retailers about any missing information. Workato automatically generates an email to the correct retailer, who can then rectify the error using a button in the email. Once they respond, Workato seamlessly moves the corrected data into the logistics management system for processing.

Related: 8 benefits of RPA software

Saving Millions by Seamlessly Escalating Major Errors to Retailers

Sometimes, a retailer’s portal doesn’t have up-to-date information. Often, this is due to an error on the retailer’s end—such as a portal being unexpectedly unavailable or an integration on their side having failed. This results in the logistics company receiving no shipment information at all for that day.

If the logistics company doesn’t receive any shipments, no shipments go out. This is a big issue for the logistic company; when shipments are delayed, the company bears full responsibility for the cost, which can top millions of dollars.

When this happened with a huge client, the retailer wanted to know why the logistics company didn’t reach out to them to let them know, despite the fact that the error was on their end. Because the logistics company relies on strong relationships with their retail clients, they needed to find a quick and effective solution that would automatically let retailers know if they did not receive any orders that day.

The logistics company created a “heartbeat check” using Workato. Using a script, Workato checks whether data is coming in from the retailer portals through the on-premise agent (OPA). If no data is flowing, Workato automatically notifies both the retailer and the company’s in-house monitoring team so they can resolve the issue ASAP.

Using Workato to solve this issue was a huge win. The logistics company was able to deploy this solution in just a week! Now the logistics company can quickly escalate issues that could delay the delivery of goods, saving them millions of dollars and strengthening their relationships with their retail clients.